Mapped Hexahedral Meshing

From NAMIC Wiki

Home < Mapped Hexahedral Meshing

Objective:

- Develop a tool for mapped meshing that will warp a template mesh onto a surface for a new subject

- Determine the limits that the warping algorithm will succeed and fail

- Apply these techniques to a sample of data to determine the reliability of the algorithm with respect to mesh quality

Progress:

- Warped meshing framework has been developed using VTK and ITK using a finite element approach

- VTK

- Support the reading and writing of meshes (vtkUnstructuredGrid) and surfaces (vtkPolyData)

- Distance measures between the deforming mesh and the subject surface

- Initial registration - Iterative Closest Point or Procrustes

- ITK

- Finite element framework used to warped the template mesh onto the subject surface

- VTK

- Registration made hierarchical to speed up the registration process

- Requires multiple template meshes to exist

- This is readily supported using the interactive meshing tools by changing the average edge length

- Subsequent meshes are initialized using a thin plate splines

- Parameters allowed to vary at each level of the registration

- Iterations

- Young's Modulus

- Convergence based on distance between the warped template and the subject surface

- User specified convergence threshold in mm

- Convergence can be based on average or maximum distance

- Boundary conditions can be applied

- Center of the mesh - Holds the eight nodes closest to the center of the mesh fixed

- External - Applies boundary conditions to the mesh as they fall within a user specified tolerance of the subject surface

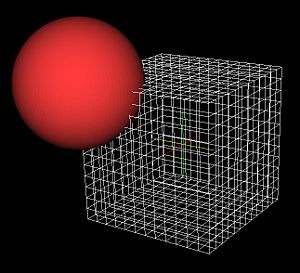

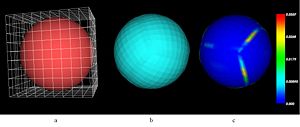

- Initial testing done by warping a cube mesh onto a sphere

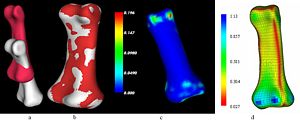

- Evaluation:

- Distance between warped mesh and subject surface

- Mesh quality

- Evaluation:

To Do:

- Further evaluation on the phalanx bones of the hand

- Convert the code into a Slicer3 execution model program

- Develop additional Slicer3 execution model programs to support complete workflow

- Assignment of material properties based in image signal intensity

- Export to Abaqus format

- Determine if there are ways to improve the speed of the algorithm

Key Investigators:

- Iowa: Nicole Grosland, Vincent Magnotta, Ritesh Bafna

Links:

Execution Model Program Description:

- To be filled in once developed

This tool was developed as part of an NIH NA-MIC Collaboration Grant EB005973.

Program Usage:

- To be filled in once developed

Figures: